FINAL DEVIATION REPORT: ISSUE 4, December 2021

DEVIATION IMPLEMENTATION REPORT: ISSUE 4, DECEMBER 2021

All photos of this project can be found in The Deviation Completion Gallery 2021

Reasons for building the Deviation

The main purpose of the Deviation construction work is to:-

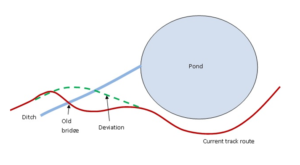

- Bypass a reverse curve containing a tight 35ft radius curve which has resulted in a history of accidents and a high rate of track wear and maintenance issues.

- Avoid the old metal bridge with a collapsing foundation leading to the likelihood of the bridge’s failure.

- Build new track pillars and improved track alignment on steel beams to provide long term solution to avoid tree roots pushing over the track.

The original route via the old bridge has deteriorated due to a combination of reasons culminating in a situation where track maintenance cannot be controlled to an adequate level. This was becoming a losing battle against nature and the deterioration of the track structures. Considering the future for the operation of the track, much careful consideration and discussion took place for providing the best all-round solution. The work on the Deviation is a long term investment in the club’s track to achieve low maintenance, improve safety and to reinstate full maintenance control.

The original route via the old bridge has deteriorated due to a combination of reasons culminating in a situation where track maintenance cannot be controlled to an adequate level. This was becoming a losing battle against nature and the deterioration of the track structures. Considering the future for the operation of the track, much careful consideration and discussion took place for providing the best all-round solution. The work on the Deviation is a long term investment in the club’s track to achieve low maintenance, improve safety and to reinstate full maintenance control.

Deviation Pre-parity Work

During the summer part of the deviation was built with seventeen of the twenty three pillars constructed and eight of the twenty four metal beams laid including the rail.

Following on from a very successful night running session on Friday 08th October the track was broken into the next day to commence the work of joining up the deviation from the main track to the extension. It was important that enough manpower capable of lifting nine heavy cast concrete beams could be brought together on that weekend.

Firstly the jumper leads across the rail joints were unscrewed, these complete the track circuit for the signals. There is lot more work involved in installing automatic colour light signalling than the majority realise. The metal anti-tip rail as far as the old bridge was dismantled and put into store. Wooden anti-tip rail beyond the bridge was removed.

Firstly the jumper leads across the rail joints were unscrewed, these complete the track circuit for the signals. There is lot more work involved in installing automatic colour light signalling than the majority realise. The metal anti-tip rail as far as the old bridge was dismantled and put into store. Wooden anti-tip rail beyond the bridge was removed.

The nine 6ft concrete beams were lifted and moved to near the plastic water tower. The track was cut in sections so that each beam could be lifted onto the works truck brought right up to each join and then rolled down the remaining track to the store. Five of the pillars were knocked down to clear ground for the realignment of the track. Although they were over 50 years old the pillars resisted the sledge hammer and could not be broken up until their solid base of concrete was dug out. At a later date the rubble will be moved to cover another blue plastic pipe to be laid in the ditch

Pillar 078 at the apex of the sharp left hand curve of the reverse curve was close to the trunk of a large tree. On demolition of this pillar it became clear why the curve could no longer be maintained as the tree itself was leaning against the pillar and gradually pushing it over altering the radius and cant of the curve.

After the metal bridge fourteen 2 meter metal beams 501 to 514 on the extension were lifted and used on the deviation. The 5 inch rail being in good condition was put into store while the 3 ½ inch rail was recycled as the 3 ½ inch on the deviation. The sleepers have

been re-used by turning them over so that new holes could be drilled into a flat surface.

Construction Work at the end of the Main Track

Between the existing track and the section of deviation already built four holes were dug/enlarged for new pillar flags laid on grit sand with 3 x 2 flags underneath the heavier 3 meter metal beam against the normal 2 x 2 flag for the 2 meter beams. A six foot lintel beam in good condition was retrieved and rolled down the old track to replace beam 276. Four new pillars were built to height plus the top face of one pillar 489 adjusted to install one of the three six foot metal beams in stock to replace the lintel beam. Two pillars had step changes built into their top surface to accommodate the deeper steel section required to strengthen the longer 3 meter beam. One 2 meter beam also has the deeper section.

Between the existing track and the section of deviation already built four holes were dug/enlarged for new pillar flags laid on grit sand with 3 x 2 flags underneath the heavier 3 meter metal beam against the normal 2 x 2 flag for the 2 meter beams. A six foot lintel beam in good condition was retrieved and rolled down the old track to replace beam 276. Four new pillars were built to height plus the top face of one pillar 489 adjusted to install one of the three six foot metal beams in stock to replace the lintel beam. Two pillars had step changes built into their top surface to accommodate the deeper steel section required to strengthen the longer 3 meter beam. One 2 meter beam also has the deeper section.

It takes three sessions to build a pillar. The positioning of the first breeze block on the base flag is critical using a 2020mm white pole for the distance between the blocks and the curve plotting tool for the correct curvature (90, 70 or 60ft radius). A second breeze block is then added and allowed to set. Only then can the remaining height of the top block be calculated including an allowance for the gradient. Blocks of varying thickness are cut to size and the number of grouts added. If the top block is thin i.e. less than 50mm it may crack when drilled so the pillar is shuttered with a wooden box and concrete poured in.

Five beams were laid as follows:- a new thick walled 2 meter beam, the 3 meter beam spanning the tree roots, then three standard 2 meter beams lifted from the extension.

There is a slight left curve then a straight past the tree followed by two transition beams curving to the right positioning the track to join up with the beams already laid on a 60ft radius curve. On the deviation there are six beams on a reducing uphill gradient averaging 1:224 then six level beams while the old track had a constant rise of 1:159 on nine beams before humping over the old bridge. The deviation is two inches lower crossing the ditch.

Laying Track on Steel Beams

The track is laid on steel beams as follows. Key sleepers are first bolted to four cross pieces welded across the beam. The rail is bent to the appropriate curve (90, 70 or 60ft radius) using the curve bending tool. The adjustment using the tightening screw is very fine and can easily result in too much or too little curve in the rail. Once the correct setting has been found then all the required rails are bent and laid out on the key sleepers.

The track is laid on steel beams as follows. Key sleepers are first bolted to four cross pieces welded across the beam. The rail is bent to the appropriate curve (90, 70 or 60ft radius) using the curve bending tool. The adjustment using the tightening screw is very fine and can easily result in too much or too little curve in the rail. Once the correct setting has been found then all the required rails are bent and laid out on the key sleepers.

The outer rail is always laid first as it has the furthest to travel round a curve. Tiny metal nails are used on each side of the rail to hold it onto the four key sleepers bolted onto each beam. The pre-curved rail is initially tied down to the first and third key sleeper. It is then checked by eye before knocking in the nails on the second and fourth sleeper. After any further adjustment the outer rail is then screwed down. The inside rail is added using the track spacers and shortened so that the two joints are opposite one another to achieve a clickerty-clack from the wheels of the trucks. The 3½ inch rail is positioned. The rest of the sleepers are then laid out and all the rails screwed down in one mammoth session.

Each steel beam has a 5mm blue plastic packer inserted underneath its end to provide a smooth surface and also to make sure that a sloping beam does not catch the edge of the flat pillar top. When laying or altering track if there is a tree nearby whose roots could lift a pillar then its height is now built 12mm lower than required. On fixing down the steel beam an additional two 6mm red packers are added to the blue packer to bring the beam back up to its correct height. The idea is that as the tree roots lift/tilt the pillar the track can be brought back level by changing the red packers to packers of lesser thickness.

Construction Work joining the Extension

To join the deviation to the extension the right hand curve to the left of the water tank from pillars 513 to 517 had to be readjusted (nudged). The 2 x 2 base flags were exposed unfortunately cutting the signal cables in four places. The proceeding pillars 511 and 512 had to be demolished and rebuilt as they were too far over to the right on a tighter curve.

To join the deviation to the extension the right hand curve to the left of the water tank from pillars 513 to 517 had to be readjusted (nudged). The 2 x 2 base flags were exposed unfortunately cutting the signal cables in four places. The proceeding pillars 511 and 512 had to be demolished and rebuilt as they were too far over to the right on a tighter curve.

The curve was reset by working backwards from pillar 517 towards pillar 511. Nudging of the base flag of the pillars with crow bars had to be undertaken a number of times to gradually realign the pillars with the resulting curve continually checked with the curve plotting tool. The curve is now at a maximum of 90ft radius on two beams as against originally at 70ft on three beams. The 630mm long fiddle beam 510 adjusted any change in the beam spacing caused by the realignment of the curve. The down gradient to the extension at 1:250 is less steep and shorter than it was from the old bridge at1:212. Wooden anti-tip rail planks were attached to the pillars with new tantalised 3 x 2 blocks.

The cant was set on the curves by adding an extra packer on top of the blue packer on one side only tilting the beam over to the appropriate degree of cant. Transition beams are used at both ends. The degree of cant is checked with a home made metal swingometer.

The signals were brought back into operation by drilling the 5inch rail either side of each fish-plate then attaching stainless steel jumpers to bridge the gap to retain continuity.

The signal cable feeds to the track were relayed under the beams and joined to the rail.

Maintenance Work

With the track closed and manpower available the opportunity was taken to work on four outstanding maintenance issues on the main track.

- Replaced deteriorating concrete lintel beam 276 with one from the deviation. NOTE that the 6ft concrete beams round the old track are starting to break up with three already replaced and two more experimental shuttered. Only two 6ft steel beams in stock. The jig to construct new ones is in the container.

- On the RHS long straight four beams 055 to 058 being tilted by trees were lifted. The top surface of the three leaning pillars were cleaned and levelled using the whizzer while the pillar next to the tree was reduced in height by12mm. The original beams were reset with their heights adjusted back to level using plastic packers.

- On the down line near the water tank beams 145 & 146 were realigned by jacking them up and then levelled on pillar 145 using packers under the two beams.

- By the station pillar 014 had been shifted 2 inches to the right by a tree. The pillar was cut down and rebuilt on a 2 x 2 flag laid on sand. Crumbling beams 014 & 015 were replaced by the last two concrete beams with packers to bring back to height..

Proposal for a Steam-fair Station

Running away from the level summit at the ditch heading towards the water tank there are five suitable straight beams on a shallow down gradient. The suggestion is that this area should be considered to see if it is feasible and if there is enough support to build a station to load passengers at the steam-fair through a gate in the fence. The station would be near to the viewing area with the big advantage of loaded trains starting downhill.

Dave Mulholland and Craig Scarisbrick